Warehouse order picking has a direct impact on operational cost, labor efficiency, throughput, and fulfillment accuracy. Choosing the right picking strategy can be the difference between smoothly scaling your business or fighting inefficiencies every day. In 2025, with e-commerce volumes and customer expectations higher than ever, understanding these methods and how technology like SKULabs supports them is essential for modern operations.

In this comprehensive guide we’ll cover:

-

What batch picking is and why many warehouses use it now

-

What single order picking is and when it’s still relevant

-

What a pick list is and how it fits into fulfillment workflows

-

Real examples and best practices

-

How technology supports these strategies

What is Single Order Picking?

Single order picking means a picker fulfills one order at a time, walking through the warehouse to collect every item for that order before moving on to the next. It is often the simplest and most intuitive picking method, especially for small operations with limited orders.

Key Characteristics

-

One picker, one order

-

Pick list contains only items for that order

-

Minimal sorting after picking

When It Works Best

Single order picking is ideal when:

-

Order volumes are relatively low

-

Most orders contain multiple items that can be picked without extensive travel

-

Fulfillment accuracy and simplicity matter more than speed

Advantages

-

Easy to train workers and manage workflows

-

Lower risk of mix-ups since each pick list belongs to a single order

-

No need for complex sorting or consolidation after picking

Challenges in 2025

While simple, single order picking can become inefficient when:

-

Order count grows beyond a few hundred per day

-

SKUs are scattered across large warehouses

-

Travel time between picks dominates labor costs

Many warehouses today avoid single order picking when they process hundreds or thousands of orders daily because pickers spend too much time walking rather than picking.

What is Batch Picking?

Batch picking groups multiple orders together so a picker collects items for several orders in one pass through the warehouse. Instead of walking for each individual order, the picker follows an optimized route based on the combined list of SKUs across orders.

Key Characteristics

-

Orders with similar SKUs are grouped into a batch

-

One pick list contains items for many orders

-

After picking, items are sorted into individual orders before packing

Current Industry Adoption in 2025

Batch picking is widely used in high-volume e-commerce and distribution centers where certain SKUs are ordered frequently across many orders. Many businesses are adopting software tools and advanced WMS or OMS to generate optimized batches, minimizing travel and labor time.

Benefits

-

Reduced travel time because pickers visit each location fewer times

-

Higher throughput and productivity with more orders picked per hour

-

Lower labor costs due to efficient routing and less duplication of effort

These benefits are especially meaningful in busy holiday peaks or when handling thousands of orders per day.

Challenges

-

Requires sorting after picking, which can add complexity

-

Best performance depends on smart batching logic

-

Not ideal for highly bespoke orders with unique SKUs

Because batch picking combines items for multiple orders, it demands robust software to plan routes and manage sorting at packing stations.

What is a Pick List?

A pick list is simply the list of items a warehouse worker must collect during a picking run. It’s central to every picking strategy, whether single order or batch picking.

How Pick Lists Work

-

Generated by a warehouse management system or software platform

-

Shows SKU, quantity, and bin location

-

Guides workers in order fulfillment

Role in Efficiency

Pick lists help warehouses:

-

Minimize missing items

-

Sequence travel through aisles logically

-

Improve order accuracy

Some operations print consolidated pick lists for batch picking. Others use mobile devices that display pick lists and point workers to the correct locations.

Pick lists are especially useful when orders are generated in real time from systems like Shopify or enterprise inventory systems, ensuring accuracy and sync with fulfillment workflows.

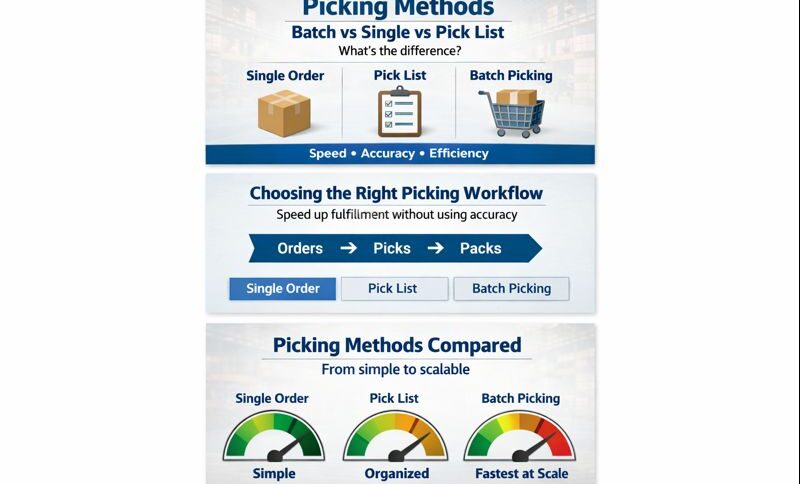

Side-by-Side Comparison

| Feature | Single Order Picking | Batch Picking | Pick List |

|---|---|---|---|

| Best for | Low volume, simple workflows | Medium to high volume fulfillment | Every picking method |

| Labor efficiency | Lower at scale | Higher | Dependent on strategy |

| Software needs | Minimal | Moderate to advanced | Essential |

| Travel reduction | Low | High | Improves all methods |

| Sorting after picking | No | Yes | Depends on batch logic |

Batch picking dramatically reduces travel time, which is one of the biggest hidden costs in fulfillment operations. Studies show that travel time is a major inefficiency in discrete methods like single order picking.

Real Warehouse Examples

Example Scenario: Small E-commerce Seller

A brand selling under 100 orders per day with limited SKU variety may find single order picking simpler and more accurate. Training is straightforward and manual processes do not hinder efficiency.

Example Scenario: High-Volume Fulfillment Center

A distribution center processing thousands of orders daily will benefit from batch picking. By grouping orders that share SKUs and organizing routes, travel time can drop significantly, freeing labor for packing and sorting tasks.

Operational Insight from Warehouses

Ops professionals often report that poor order picking strategy leads to excessive walking and reduced throughput. Switching to batch methods or hybrid strategies can unlock productivity gains without needing high-end automation right away.

How Modern Software Supports Picking

Technology plays a growing role in optimizing picking strategies in 2025. Warehouse management systems, order management systems, and platforms like SKULabs help by:

-

Generating optimized pick lists for batch or single order workflows

-

Assigning picking routes that minimize travel time

-

Syncing orders and inventory from ecommerce platforms like Shopify

-

Tracking fulfillment progress in real-time across multiple picking strategies

This means businesses can:

-

Scale more efficiently

-

Adapt picking strategies based on order volumes

-

Maintain accuracy even as order profiles change

Whether a warehouse wants to pick large batches, handle single key orders, or switch between methods dynamically, software that understands SKU locations, real-time inventory, and optimized workflows is crucial.

Choosing the Right Picking Strategy in 2025

No single method is perfect for all operations but understanding your order profiles, SKU complexity, and volume patterns will help determine the right approach:

Single Order Picking

Best for low volume, high complexity orders, or bespoke fulfillment.

Batch Picking

Ideal for high volume, similar SKU patterns, and when labor efficiency is critical.

Pick List

Essential tool across all methods. Enhances accuracy and workflow execution.

Software that supports multiple picking strategies and creates smart pick lists will future-proof warehouse operations as volumes grow and fulfillment demands increase.

Whether you are running a small operation or managing thousands of orders per day, choosing the right picking strategy can have a measurable impact on speed, accuracy, and labor efficiency. Many warehouses in 2025 are moving away from one-size-fits-all workflows and instead using flexible picking methods that adapt as order volume and complexity change.

If you are evaluating batch picking vs single order picking, looking to improve your pick list workflow, or trying to reduce warehouse travel time and fulfillment errors, the right technology can make all the difference.

At SKULabs, we work closely with fulfillment and operations teams to understand real-world workflows and help configure picking strategies that actually scale. Whether you are just getting started or refining an existing process, our team is here to help.

Reach out to SKULabs to schedule a conversation or demo and see how modern fulfillment software can support your warehouse today and as you grow.