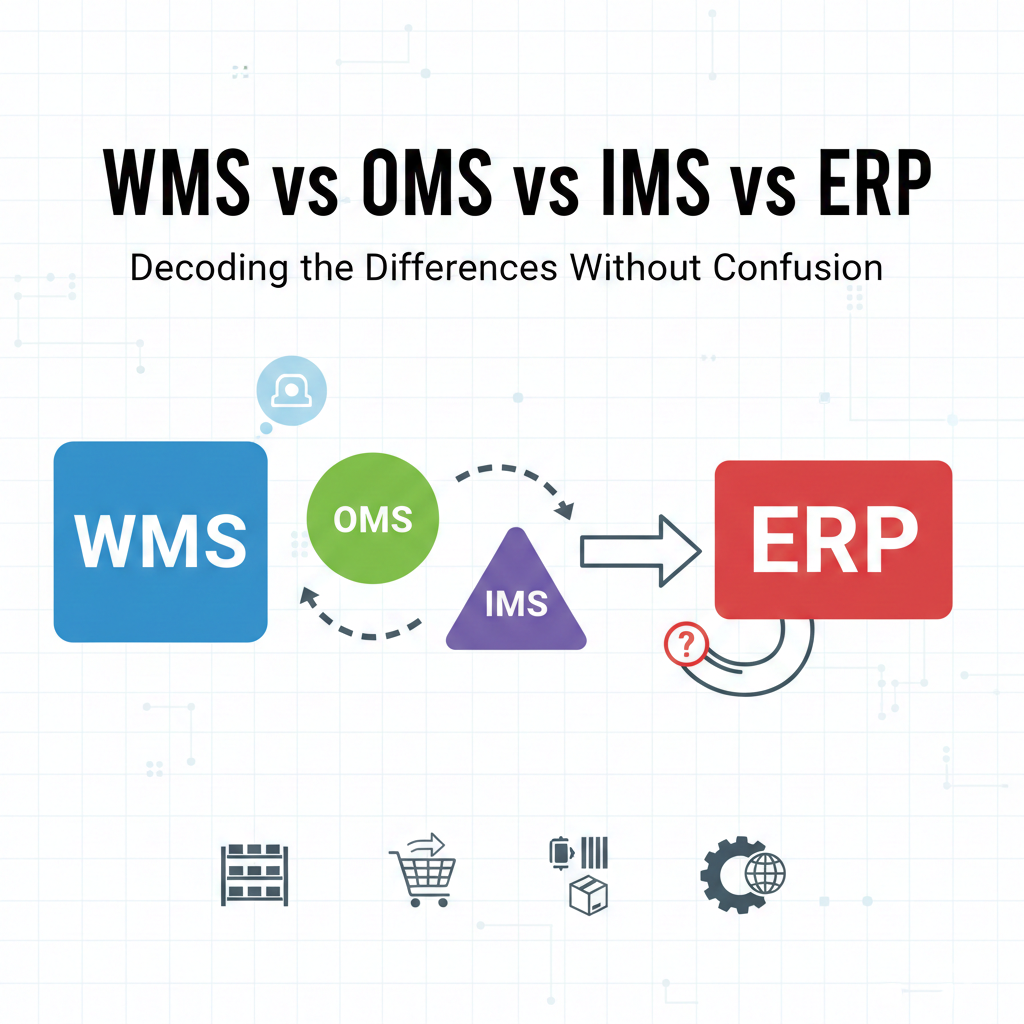

Businesses that handle physical products often reach a point where spreadsheets, basic integrations and manual processes no longer keep up with growing demand. This is when decision makers begin searching for a platform that can coordinate inventory, orders, fulfillment and operations at scale. The confusion begins when four common software categories appear in the search results. WMS. OMS. IMS. ERP.

Each of these systems solves a different part of the operations puzzle. Many companies believe they need all of them, which leads to expensive choices, long onboarding cycles and software overlap. This guide breaks down the differences in simple terms so that any growing brand can decide what they truly need.

What is a WMS

A Warehouse Management System focuses on what happens inside your warehouse. It supports picking, packing, shipping, barcode driven workflows, real time location control, warehouse layout and labor efficiency. Companies with large order volume or multiple warehouse zones often rely on a WMS to ensure workers move quickly and errors stay low.

Key capabilities of a WMS

-

Real time picking and packing guidance

-

Barcode scanning

-

Automated shipping label creation

-

Putaway logic

-

Cycle counting and audits

-

Worker productivity reporting

A WMS is ideal when warehouse speed and accuracy are the main challenges.

What is an OMS

An Order Management System focuses on the customer order lifecycle. It centralizes every order from every sales channel and ensures that payments, status updates, routing and fulfillment decisions are handled correctly. Brands selling online through multiple channels often use an OMS to prevent overselling or missed orders.

Key capabilities of an OMS

-

Centralized order intake

-

Order routing rules

-

Fraud review and payment status validation

-

Fulfillment status updates

-

Customer service order visibility

An OMS is ideal when multichannel visibility and order accuracy are the main challenges.

What is an IMS

An Inventory Management System focuses strictly on inventory counts across every location. It does not manage warehouse labor and it does not manage the entire order workflow. Instead, it ensures that your stock levels stay accurate. Growing brands adopt an IMS when stockouts, overselling and inaccurate counts disrupt day to day operations.

Key capabilities of an IMS

-

Real time stock levels

-

Inventory updates across multiple channels

-

Purchase order tracking

-

Stock alerts

-

Kitting and bundling logic

An IMS is ideal when accurate counts and multichannel availability are the main challenges.

What is an ERP

An Enterprise Resource Planning system connects the full business. Accounting. Finance. Manufacturing. Purchasing. Inventory. Human resources. Production planning. Large corporations use ERPs because they need a single source of truth for every department. Most small and mid sized businesses do not start with an ERP because these systems can be expensive and complex.

Key capabilities of an ERP

-

Financial management

-

Procurement

-

Production and manufacturing planning

-

Inventory control

-

Sales order management

-

Reporting across all departments

An ERP is ideal when many departments need to operate on a unified platform.

Which system does your business really need

Here is a simple way to decide.

If your main problem is warehouse speed and accuracy, you are looking for a WMS.

If your main problem is order volume and multichannel selling, you are looking for an OMS.

If your main problem is inaccurate counts and overselling, you are looking for an IMS.

If your main problem is cross department alignment with finance, production and purchasing, you are looking for an ERP.

Most growing ecommerce brands do not need four systems. They need one system that covers the core operations they rely on every day.

This is where SKULabs fits perfectly.

How SKULabs Solves WMS, OMS and IMS Challenges in One Platform

SKULabs is a unified operations platform that combines the power of a WMS, OMS and IMS in a single solution. It is built for ecommerce and wholesale brands that want fast fulfillment, accurate inventory and complete order visibility without the complexity or cost of a full ERP.

SKULabs supports

-

Real time multichannel inventory control

-

Centralized order management

-

Advanced picking and packing workflows

-

Barcode driven accuracy

-

Integrated shipping with every major carrier

-

Purchase order management

-

Lightning fast onboarding compared to ERP systems

Because SKULabs connects to all major sales channels, it prevents overselling and syncs stock levels instantly. Because it includes full warehouse workflows, it improves the speed and accuracy of every pick and pack operation. And because it centralizes orders, it gives your team clear visibility into every customer purchase from start to finish.

For most growing brands, SKULabs replaces the need for separate WMS, OMS and IMS tools. This reduces software spending, shortens training time and eliminates data silos that cause mistakes.

What This Means for Your Team

If you want to simplify operations, eliminate overselling, speed up fulfillment and centralize every order in one place, SKULabs is the platform built for your team. Book a demo today and see how your business can operate with the accuracy and efficiency of a fully unified system.

Start your SKULabs demo now and take control of your entire operation from inventory to shipping.